General software description

The WinARace 2D data analysis software is the result of more than 30 years of collaboration with data engineers in highly professional motorsports (MotoGP, F1, etc.). In this field of use of data analysis, software must be designed for speed and for dynamic situations on the one hand, and on the other hand it must also be suitable for long-term data analysis, so that changes to the vehicle can be tracked and validated at any time.

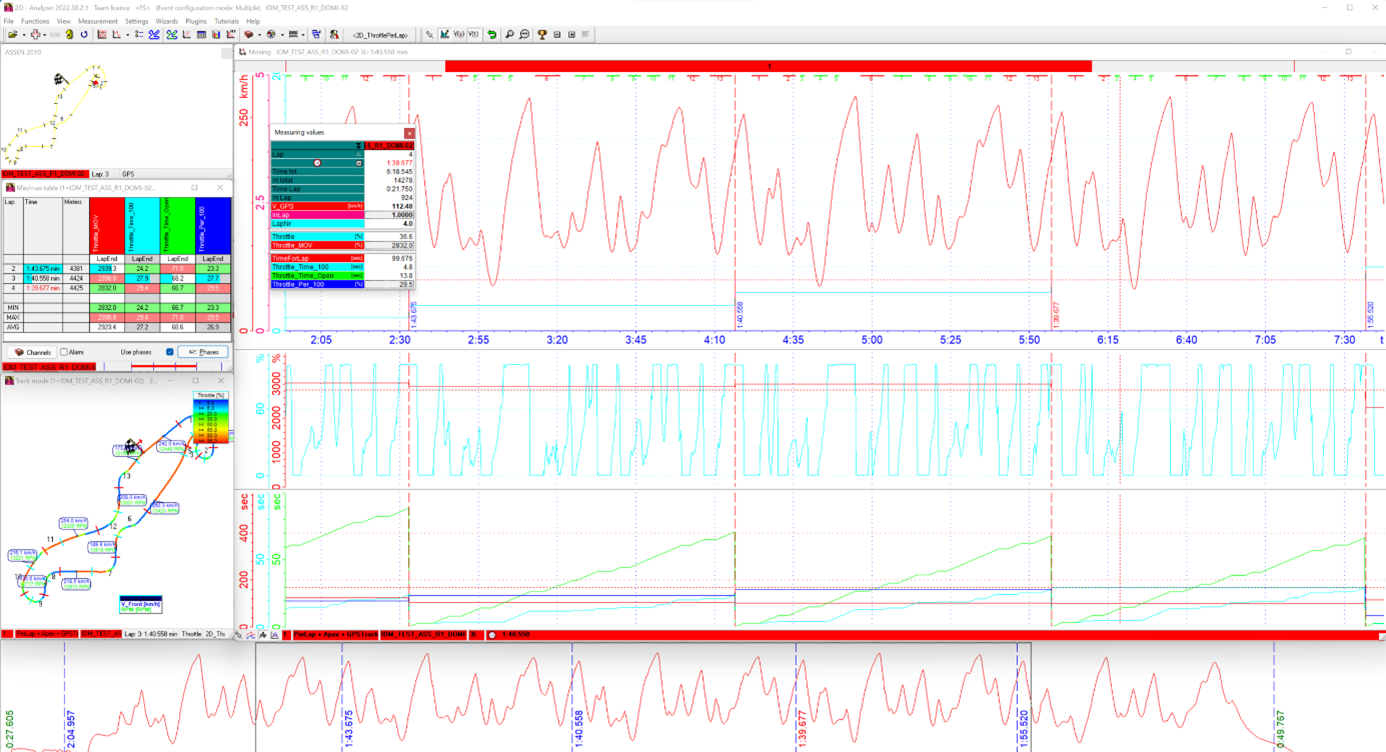

For the former, the 2D analysis software offers the possibility of preparing various templates, plots (min/max table, XY diagrams, histograms, FFT …), as well as lap and section time evaluations, in order to be able to provide the driver between sessions, tailored to the respective situation, with the most important information quickly and easily prepared.

The Analyzer’s feature set includes the ability to load any number of measurements simultaneously so that differences can be compared directly.

Using the GoPro AutoSync feature, it is also possible to conveniently synchronize videos from up to four GoPros with the measurement data, thus adding an audiovisual component to the analysis.

Since the 2D analysis software also includes a post-processing calculation tool called CalcTool, the original recorded channels can be further processed using a variety of mathematical operations and 2D-specific calculation functions. Newly created or improved evaluation algorithms can then be applied retrospectively to previously recorded measurements as often as desired. Various extensible toolchains (GPS-Postprocessing, GPSTracks, IMU Filter and Rotate, …) help the user to improve the analysis and to adapt it to his own needs.

For online calculations during data recording, the so-called CALC channels of the various 2D modules can be used, which can further process the received signals in real time, record them if necessary, and in turn also send them as new measurement channels to the CAN bus.

Likewise, race data analysis software must be designed to organize measurement data within a team and ensure permanent traceability to vehicle, driver or environment parameters. For this purpose, a customizable meta-database is used, which is available for each measurement as a so-called SpecSheet. Therefore, the complete meta data documentation can be done consistently via the 2D SpecSheet. The SpecSheet of a measurement can be accessed by the user either manually or by reading and writing via the CalcTool in order to use the SpecSheet parameters (e.g. vehicle mass, spring rates, tire sizes, …) for calculations or to write calculation results back into the SpecSheet for documentation purposes.

It is also possible to automate the 2D software to such an extent that directly after the measurement download, it automatically executes the points described above and creates for the user an Excel evaluation sheet defined via a template with all important parameters or plots at any storage location (e.g. network drive), so that it can be accessed directly from a tablet, for example, quickly and regardless of location. In addition to the use of the 2D measurement systems and evaluation software in racing, the 2D modules (New Hardware Modules 2022) and the software are also increasingly used in development tasks in various other areas (vehicle development, …) and sports (mountain biking, skiing, trampolining, …).

To pick up on the points mentioned above, it is very helpful to conclude with an example in which the influence of the changes to the suspension strut linkage on the balance of the vehicle is to be checked:

Over various test events, always on the same test track, the suspension strut linkage was modified each time and the changes documented in the measurement-specific SpecSheet. Now the aim is to check which setting is best suited to the balance of the vehicle at the upcoming race. On the one hand, the measurements of the test events can be loaded simultaneously in the Analyzer so that the original recorded suspension travel signals can be superimposed and analyzed. On the other hand, it is possible to use the CalcTool and the LapChannels toolchain provided to calculate the absolute travel covered by the suspension strut on a lap-by-lap basis and to store this in the SpecSheet, which can provide information about the linkage at which the suspension works most effectively. This calculation of the absolute travel of the suspension thus generates exactly one value per lap, with which a specific behavior is described. The 2D software is then able to transfer SpecSheet values of selected measurements into a prepared Excel sheet, thus enabling a long-term, clear evaluation. Using freely definable GPS trigger coordinates, individual sections can also be defined, which can then be used to calculate other interesting parameters such as RMS/VDV/AVG/MAX/MIN for specific sections only, and then exported.

Screenshot 2D Analyzer